Mixing-Charging Machines for Open-Pit Mining

Modern solutions for efficient and safe borehole charging

16 t

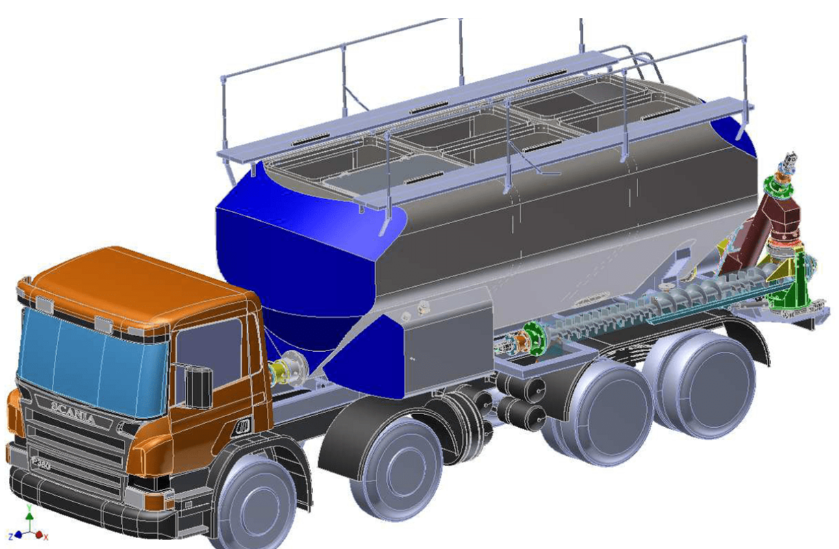

16 tMSZ-16 (chassis 6×4; 6×6; 8×4)

Sibirit® EE — manufactured during charging

8х4.jpg) 16/20 t

16/20 tMSZ-16(20t) (chassis 8×4; 8×8)

Sibirit® EE — HL version for cold climate

16 t

16 tMSZ-16UN (chassis 6×4; 6×6; 8×4)

Any emulsion explosives — weight dosing

.png) 20+ t

20+ tMSZ-20UT

Emulsion and blended explosives — universal machine

20 t

20 tMSZ-20 (quarry chassis)

Sibirit® EE on BelAZ and similar chassis

~17 t

~17 tMSZ-17Gr

Industrial granular explosives (ANFO)

15 t

15 tMSZ-15Gr (chassis 6×6; 6×4; 8×4)

Industrial granular explosives — MEMU

14 t

14 tMSZ-14SM (chassis 6×6; 6×4; 8×4)

Blended explosives — EE + ANFO